Assembly Excellence

Complex multi-component integration with contamination-free assembly environments and comprehensive quality checkpoints. From component preparation through final testing and validation.

Step-by-Step Assembly Workflow

From component preparation through final testing, every step is engineered for precision and quality

Component Preparation

Inspection, cleaning, and verification of all components before assembly

- Visual inspection

- Dimensional verification

- Contamination control

- Material traceability

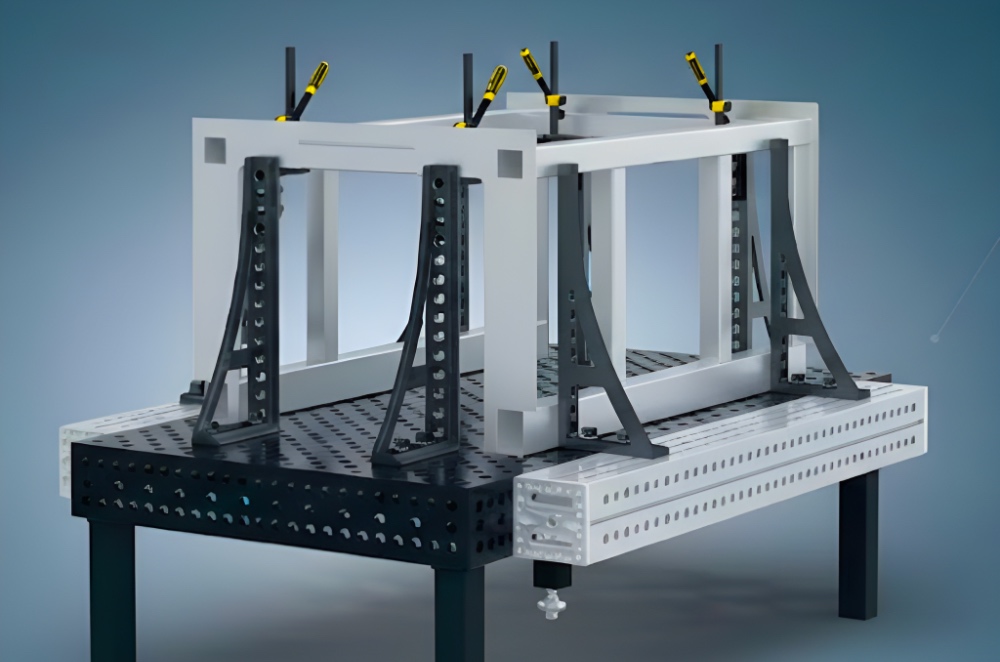

Precision Assembly

Expert integration using specialized fixtures and precision torque specifications

- Controlled environment

- Precision torque tools

- Assembly fixtures

- Step-by-step procedures

Quality Checkpoints

Comprehensive inspection and testing throughout the assembly process

- In-process inspection

- Dimensional checks

- Functional testing

- Documentation

Final Validation

Complete testing and certification before delivery

- Performance testing

- Quality certification

- Final inspection

- Packaging & delivery

Assembly Capabilities

Specialized equipment and expertise for complex multi-component integration

Precision Torque Control

Calibrated torque tools with documented specifications for every fastener

- ±2% torque accuracy

- Digital torque wrenches

- Calibration certificates

- Torque documentation

Contamination Controlled Environment

Controlled assembly areas for semiconductor and medical device applications

- Class 10,000 cleanroom

- ESD protection

- Particle monitoring

- Gowning protocols

Component Compatibility

Expert knowledge of material combinations and joining techniques

- Material compatibility

- Thermal expansion

- Galvanic corrosion

- Specialized fasteners

Quality Checkpoints

Comprehensive inspection and testing throughout assembly process

- In-process inspection

- Dimensional verification

- Functional testing

- Final validation

Specialized Assembly Fixtures

Custom fixtures and tooling designed for your specific assembly requirements, ensuring consistent quality and repeatability.

- Custom fixture design and fabrication

- Precision measurement and alignment tools

- MBD product simulation

- Automated testing equipment with Absolute Arm 7-Axis delivers tactile probing and non-contact scanning measurement to ultra-high accuracy.

Comprehensive Quality Systems

Real-time monitoring, statistical process control, and comprehensive testing methodologies

Real-Time Monitoring

Live tracking of assembly progress with digital work instructions and quality checkpoints

Statistical Process Control

Data-driven quality management with trend analysis and continuous improvement

Comprehensive Testing

Multi-stage testing protocols ensuring complete product integrity

Full Traceability

Complete documentation from component receipt through final delivery

Industry-Specific Assembly Solutions

Specialized assembly protocols for semiconductor, medical device, and aerospace applications

Semiconductor

- Ultra-clean assembly

- ESD protection

- Particle control

- Full documentation

Medical Devices

- FDA compliance

- Biocompatibility

- Sterile assembly

- Validation protocols

Aerospace

- AS9100 certified

- Material traceability

- NDT inspection

- First article inspection

Seamless Workflow Integration

Assembly connects welding and coating processes for complete manufacturing solutions

Welding Excellence

Certified welding processes with contamination control

Powder Coating

Advanced coating systems for superior finish quality

Ready for Precision Assembly?

Partner with our assembly experts for complex multi-component integration with comprehensive quality assurance and full traceability.

Expert Assembly

Specialized fixtures and precision torque control

Quality Assurance

Comprehensive testing and validation protocols

Full Traceability

Complete documentation and certification packages