Powder Coating Mastery

Zirconium treatment chemistry and conveyor-scale capabilities delivering superior coating performance. From pre-treatment to final cure, every step engineered for excellence.

Engineered Coating Process

Every coating cycle follows our proven four-stage methodology, combining advanced chemistry with precision process control for superior finish quality.

Pre-Treatment

Step 1Zirconium-based conversion coating creates superior adhesion foundation with enhanced corrosion resistance.

Powder Application

Step 2Electrostatic spray technology ensures uniform coating distribution with optimal film thickness control.

Thermal Cure

Step 3Precision temperature profiling achieves complete cross-linking for maximum durability and finish quality.

Quality Verification

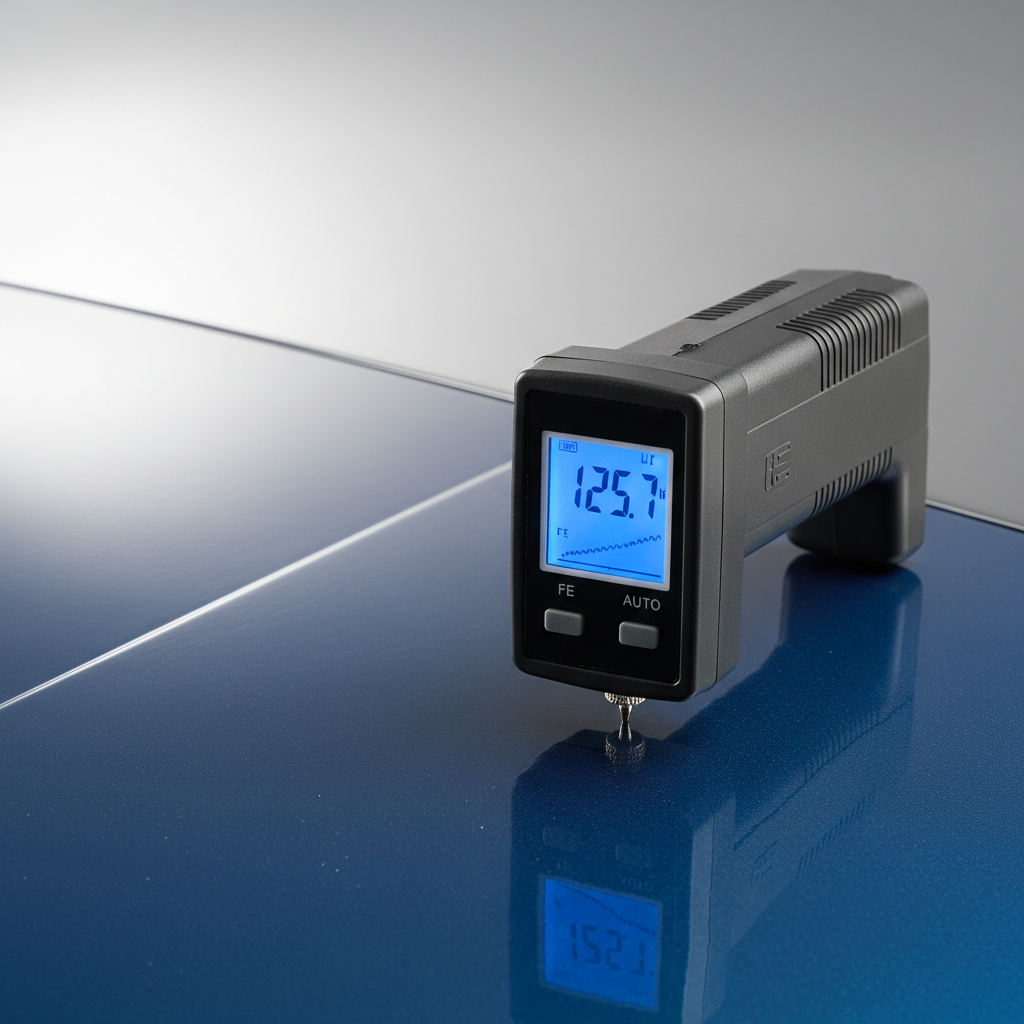

Step 4Multi-point inspection protocol validates adhesion, thickness, appearance, and performance specifications.

Detailed Process Walkthrough

Explore each stage of our powder coating process with comprehensive visual documentation and technical details.

Pre-treatment

Advanced zirconium-based chemistry for superior adhesion and corrosion resistance. Multi-stage cleaning and surface preparation.

Key Activities

- Alkaline Cleaning

- Zirconium Conversion Coating

- Multi-Stage Rinsing

- Surface Quality Verification

Pre-Treatment Chemistry Protocols

Our zirconium-based conversion coating system delivers superior adhesion and corrosion resistance through precise chemical control.

Alkaline Cleaning

Removes oils, greases, and organic contaminants from substrate surface

Acid Rinse

Neutralizes alkaline residue and etches surface for improved adhesion

Zirconium Conversion

Creates nano-ceramic conversion layer for superior corrosion protection

DI Water Seal

Final rinse removes residual chemistry and prevents water spotting

6-Stage Zirconium Pre-Treatment

Our proprietary pre-treatment process creates a nano-ceramic conversion coating that provides exceptional adhesion and corrosion resistance.

Alkaline Clean

Remove oils and contaminants

Rinse

DI water rinse

Zirconium Bath

Nano-ceramic conversion coating

Rinse

DI water rinse

Seal

Non-chrome seal rinse

Dry-Off

Forced air dry

Zirconium Bath Chemistry

Daily titration ensures consistent coating weight and performance. Full chemistry SOP available upon request.

Chemistry Control & Monitoring

All pre-treatment baths are monitored continuously with automated titration systems. Daily lab analysis validates concentration, pH, and contamination levels. Bath chemistry is adjusted or replaced based on strict performance criteria to maintain optimal coating adhesion and corrosion resistance.

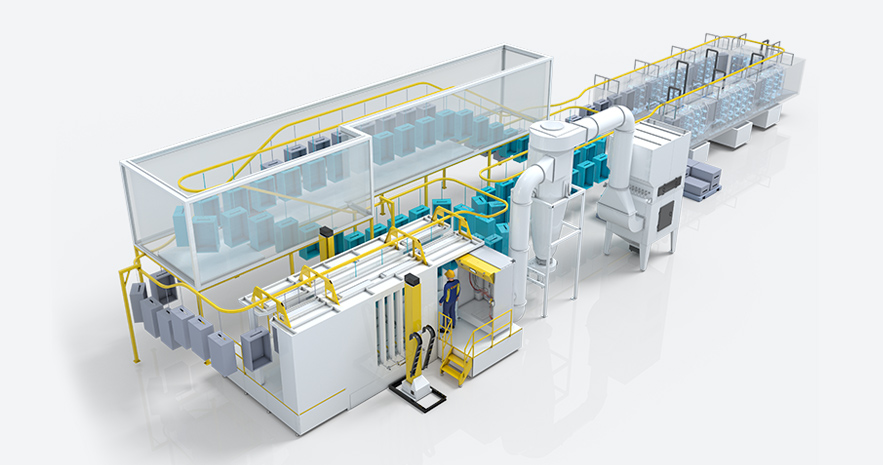

Conveyor System Deep Dive

Click the hotspots to explore technical specifications of our automated powder coating line.

Quality Checkpoint System

Multi-stage inspection protocol validates coating performance at every critical process step. Our systematic approach ensures consistent quality and long-term durability.

Pre-Treatment Verification

Complete water sheeting, 50-150 mg/ft² coating weight

Powder Application

2-4 mils thickness, uniform coverage, no holidays

Cure Verification

>100 double rubs, ≥2H hardness, ±5 gloss units

Final Inspection

5B adhesion rating, no coating failure at 160 in-lbs

Color & Finish Capabilities

From standard architectural colors to custom formulations, our coating library delivers the exact finish your project demands.

Architectural Series

AAMA 2604/2605 compliant coatings for exterior building applications

Industrial Protection

Heavy-duty epoxy and polyester formulations for harsh environments

Custom Colors

RAL, Pantone, and custom color matching with spectrophotometer verification

Specialty Coatings

Functional coatings including anti-microbial, conductive, and high-temp

Custom Color Matching Service

Our spectrophotometer-equipped lab can match any color sample with precision. Submit your reference for a custom formulation quote.

Coating Durability Testing

Comprehensive ASTM testing validates coating performance across critical durability metrics. Every result backed by certified lab data.

Salt Spray Resistance

Validates long-term corrosion protection in marine and industrial environments

Adhesion Cross-Hatch

Confirms superior coating-to-substrate bond strength and durability

Impact Resistance

Demonstrates coating flexibility and resistance to mechanical damage

Pencil Hardness

Indicates coating hardness and scratch resistance for handling durability

Gloss Retention

Proves UV stability and long-term appearance retention in outdoor exposure

Chemical Resistance

Validates coating integrity when exposed to cleaning agents and chemicals

Testing Certification & Documentation

Available Test Reports

Quality Assurance

Ready for Superior Coating Performance?

Experience the difference of precision chemistry and systematic quality control. Let's discuss your coating requirements.

Fast Turnaround

24-48 hour typical turnaround for standard coating projects with rush service available

Quality Guaranteed

ISO 9001:2015 certified processes with comprehensive testing and documentation

Custom Solutions

Color matching, specialty coatings, and custom chemistry formulations available

Need technical specifications or have questions about coating chemistry?